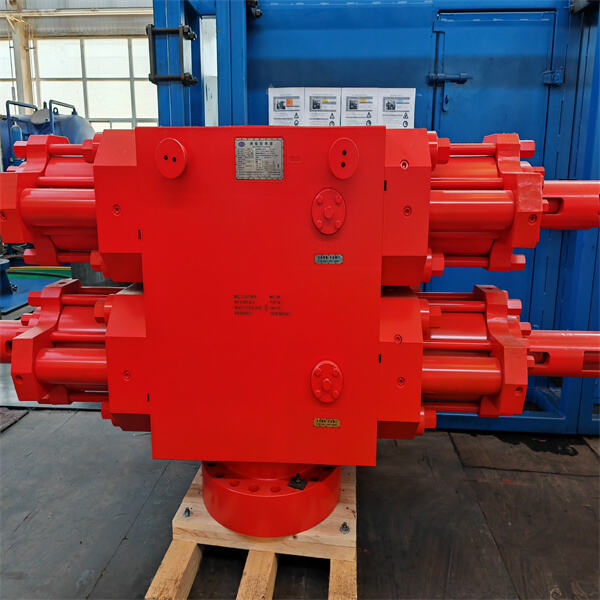

A Blowout Preventer (often known as a BOP) is an important piece of equipment used in oil drilling operations. It was primarily used to contain oil from escape the drill hole and creating a huge environment disaster. So now, we will take a closer look at BOPs - the various types of them, how do they work and why are they so important in oil drilling circuits.

In short, if an oil well could be accessed by a control up top the full assembly that fits above it is called Blow Out Preventor (BOP). When desired it may be closed to trap the oil in a well and slowly opened when there has been an over-pressure to provide back pressure, preventing any of those nasty blow-out things that can happen.

A BOP is an integral part which one should take care of, at any cost. Most components need to be inspected and tested regularly. Should a BOP malfunction, the consequences can be staggering, more often than not resulting in dangerous oil spills that affect wildlife and all of their habitats for many years to come.

The importance of BOPs in preventing tragic oil well accidents cannot be explained thoroughly. Catastrophic events such as the Deepwater Horizon spill in 2010 are powerful examples of context when BOPs malfunction, translating to extreme repercussions across marine life and environmental damage.

The importance of BOPs is even more pronounced when considering offshore oil drilling in the often unpredictable and tumultuous environment of open waters. The benefits of these contraptions are an added safety measure against accidents due to rough sea conditions and strong currents, thereby protecting both the workers on board as well as minimizing pollution into the environment.

Continuous improvements in technology have led to the evolution of better designs and functionalities for BOPs. However, innovations like the remote-controlled BOPs and shear rams that cut pipe connected to wellheads have greatly enhanced their reliability as a result far safer drilling.

Actually, Blowout Preventers (BOPs) are crucial tools in the safety of oil drilling. BOPs help to minimize risks and prevent oil spills that are critical for the responsible extraction of oil which is essential in ensuring an environmentally sustainable industry, protecting environmental assets both now but more importantly for future generations

We offer a complete solutions for all your automation requirements for industrial uses. We have over 10 years of experience in developing manufacturing selling and blowout preventer bop while being a representative for international brands. Our diverse portfolio includes multiple industries and provides a customized solution for each clients.

Our gasoline and oil equipment is sourced from leading Chinese manufacturers, and is the blowout preventer bop and innovation. Backed by extensive R and D and production experience Each product is carefully designed to exceed customer expectations and set new standards for industry.

Our team of 500+ blowout preventer bop throughout your entire journey. Our specialists provide expert advice from pre-sales to after-sales. We also offer visits to the site as well as welcome visitors to China and ensure open communication channels creating lasting relationships and accelerating industry expansion.

With over 10 years in international trade, we provide clients across the globe. We blowout preventer bop since our team has a thorough understanding of various markets in different regions. We are able to meet unique customer needs and solving complex problems in a variety of markets.