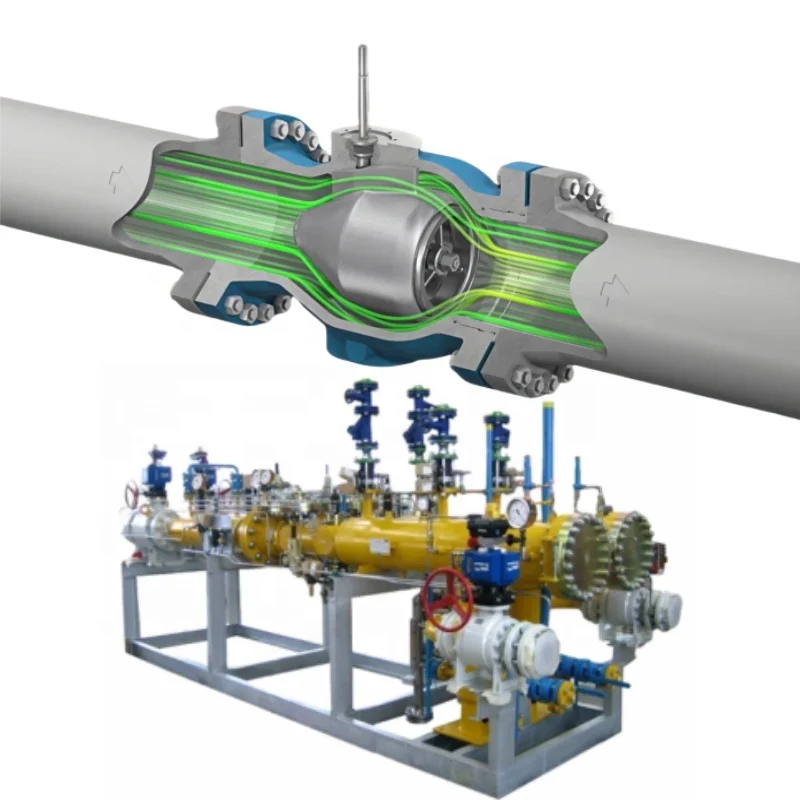

Pneumatiske ventilstillinger er av ytterste viktighet i de fleste maskiner. Ved hjelp av lufttrykk regulerer de hvor åpen eller lukket en ventil er. Noen ganger er lufttrykket feil, og ventilstillingen oppfører seg unormalt eller går ut av drift midlertidig. Slike problemer kommer og går, og det kan være vanskelig å forstå hvorfor. Når en ventilstiller slås ut på denne måten, kan det bremse arbeidet eller skade maskiner. Hos Xiangjing kjenner vi disse problemene godt, fordi vi produserer tusenvis av ventilstillere. Vi ønsker å vise deg hvorfor denne pneumatiske feilen kommer og går, slik at maskinen din kan fungere uten problemer.

Vanlige luftproblemer i stilleverk for reguleringsventiler og hvordan de kan unngås

Av og til oppstår det problemer med luften i kontrollventilposisjonserer og det skjer bare spesielt av og til. En grunn er små lekkasjer i luftslangene eller tilkoblingene. Luft lekker sakte ut, og ventilen åpner ikke ved riktig trykk hver gang. Tenk på en ballong med et hull i – den vil ikke holde seg fullt oppblåst for alltid. En annen årsak kan være at deler inne i posisjonsstyret er smussete eller har klebrig forurensning. Små åpninger kan være tette av støv eller olje, noe som gjør det vanskelig for luft å passere. Det fører til at ventilen ikke reagerer korrekt eller raskt nok. Tilfeldigvis kan lufttilførselen også variere mye i trykk, noe som forvirrer posisjonsstyret. Å løse disse problemene kan innebære å undersøke slangene etter hull eller løse koplinger. Å forsiktig tørke rene indre deler kan også hjelpe. I noen tilfeller må slitte deler byttes ut for å stanse lekkasjer eller tettløp. Vi ser at selv de minste lekkasjene eller små mengder smuss kan føre til store problemer. Forsink derfor ikke enkelte reparasjoner, for de kan utvikle seg til større problemer senere. Å rette opp disse feilene sørger for at posisjonsstyret ditt fungerer som det skal – og holder lommeboken din lukket!

Pålitelige ventilstillingsautomater bygget for kontinuerlig ytelse - Hvorfor Xiangjing er det trygge valget

Når det gjelder behovet for ventilstillere som bokstavelig talt fungerer hele tiden, bør du sørge for å kjøpe dem fra en pålitelig leverandør. Grossisttilbud av utmerket og stabil pneumatisk ytelse fra ventilstiller – Xiangjing tilbyr store mengder ventilstillere med høy stabilitet. Når du kjøper fra oss, betyr det at du bruker produkter som er tenkt igjennom og nøye kontrollert. Med store innkjøp av ventilstillere fra Xiangjing kan du være sikker på at de holder maskinene i drift uten plutselige stopp. Vi bruker kun kvalitetsmaterialer og presisjonsferdigung for å eliminere lekkasjer allerede fra begynnelsen. I tillegg tilbyr vi solid støtte og råd slik at du vet hvordan du betjener og vedlikeholder ventilstillerne dine. Dette hjelper til å unngå mange vanlige problemer. Mange kunder sier at gode ventilstillere fra Xiangjing gjør at virksomheten deres blir bedre og mer effektiv. Det er avgjørende med deler som passer sammen og fungerer godt. Hvis ventilstillerne kommer fra ulike steder og har ulik kvalitet, kan alvorlige feil oppstå. Ved å velge Xiangjing reduserer du disse risikoen betraktelig. Vårt merke handler om å levere førsteklasses produkter som yter uten overdrevet markedsføring og aldri overlater brukeren i stikken under arbeid.

Kva er den beste tilnærminga til å diagnostisere feil på intermittente ventilposisjoneringsapparat?

Intermitterande ventilposisjoneringsfeil kan vera vanskelege å diagnostisere og korrigera på grunn av at dei ikkje alltid er til stades. Ein posisjoner er ei anordning som hjelper til med den presise posisjoneringen av ventilen med lufttrykk. Når det fungerer som det er konstruert, opnar eller stengjer ventilen seg i rett tid; hvis det ikkje fungerer som det skal, så flyttar ventilen ikkje på den forventade måten. Nokre av dei beste måtane å diagnose slike problem er: Først og fremst bør du kontrollere lufttilførselen din. Pass på at det er eit reint, jevnt lufttrykk fordi ventilposisjoneringsapparatet kan oppføra seg uregelmessig om du har skitent eller lågt lufttrykk. I Xiangjing meiner me at du ikkje skal bruka noko som ikkje er reint og tørr for å unngå desse problemane. Sjekk deretter dei mekaniske delane av pneumatisk ventilposisjonserer . Av og til kan søppel som smuss, støv eller rust tette igjen små komponenter i enheten. Ved å holde disse delene rene og godt smurt unngår du feilfunksjoner. Vær også nøye med å observere hvordan ventilstillingen endrer seg over tid. Enkle verktøy som et ur, eller til og med videoopptak, kan brukes for å se når ventilen ikke beveger seg som den skal. Det hjelper også å være oppmerksom på uvanlige lyder, som sissing eller klikkelyder, som kan indikere luftlekkasjer eller slitte deler. Diagnostisering av periodiske problemer Når du har et periodisk problem, bør ytelsen til ventilstilleren testes under flere forhold (endringer i temperatur, fuktighet), fordi driftsfaktorer ikke er konstante. Under testing anbefaler vi at teknikere tar mange notater og fører gode logger, slik at det blir enkelt å se mønstre i feil, råder Xiangjing. Til slutt, sørg for å inspisere ledninger og elektriske signaler dersom ventilstilleren har elektroniske deler. Dårlige kontakter og svake signaler kan få enheten til å slutte å fungere av og til. Å følge disse beste metodene gjør det lettere å lokalisere hyppige men vanskelige å diagnostisere feil hos ventilstilleren og bidrar til å minimere nedetid.

Hvordan utføre kvalitetskontroll i pneumatiske ventilstillere?

Spesialkjøpere gjør spesielt mye for å holde pneumatisk ventilstilling fungerende godt og i lang tid. Når man kjøper et stort antall ventilstillinger, er det avgjørende å inspisere dem for kvalitet før du foretar betaling. Hos Xiangjing ivaretar vi kvalitetskontroll under hele prosessen med å velge leverandør og opprettholder strenge produksjonsstandarder. Kjøpere bør alltid be om produktsprøver og teste disse sprøvene før de går til større ordrer. Å avgi prøver hjelper til med å avdekke eventuelle problemer tidlig – som luftlekkasjer eller deler som rett og slett ikke passer godt. En annen måte å vurdere kvalitet på, er å sjekke om ventilstillingene overholder bransjestandarder og har sertifikater eller testrapporter som dokumenterer dette. Dokumentene viser at produktene er undersøkt av eksperter og oppfyller krav til sikkerhet og ytelse. Undersøkelse ved mottak anbefales også sterkt. Spesialkjøpere må inspisere hver sending for skader eller defekter. Ventilstillinger kan være ubrukelige når de ankommer – spesielt hvis de har vært utsatt for hard transport og lasting – men kontroll, tømming osv. kan forebygge problemer senere. For å unngå slike ulykker, anbefaler Xiangjing at du bruker enkle verktøy, som trykkmålere og lekkasjedetektorer, for å teste hver ventilstilling før den tas i bruk. En annen viktig tiltak er å trene arbeidere som jobber med og installerer ventilstillinger. Ved å lære ansatte hvordan de skal bruke og ta vare på disse maskinene, er det mindre sannsynlig at de blir skadet eller svikter. Kjøpere bør også samarbeide tett med leverandører for raskt å løse kvalitetsproblemer. Godt håndtert kommunikasjon kan rette opp feil før de forårsaker store problemer med mange produkter. Til slutt kan kjøpere etablere et system som registrerer tilbakemeldinger på kvalitet, der de lagrer poster over identifiserte problemer og hvordan de ble løst. Denne metoden nytter fremtidige innkjøp og sikrer høyere standarder. Ved å gjøre dette, kan spesialkjøpere sikre seg at de pneumatiske ventilstillingene de investerer i, som Xiangjing, yter godt og bidrar til sikre og effektive operasjoner.

Relevante diagnostiske verktøy som er populære på markedet for feil ved pneumatiske ventilstillinger

I dag hjelper mange moderne teknikker teknikere med å diagnostisere problemer på pneumatisk ventilstilling mye raskere og mer nøyaktig. Disse nye diagnostikkverktøyene er viktige fordi ventilstillinger kan utvikle komplekse problemer som er vanskelige å se med blotte øyne eller høre med ørene. Ett av de populære verktøyene som brukes, er et digitalt trykkmåler. Denne enheten viser i sanntid lufttrykket ved ventilstillingen. Hos Xiangjing brukes digitale trykkmålere for å sikre at lufttrykket er stabilt og at det ikke oppstår plutselige fall, noe som kan føre til intermittente feil. Ultralykkelokator er et annet deteksjonsmiddel som kan benyttes. Denne apparaten lytter etter høyfrekvente utslipp fra luftlekkasjer som er uhørbare for menneskelige ører. Å oppdage og rette opp luftlekkasjer i et tidlig stadium bidrar til en lang levetid for ventilstillingen. En bærbar vibrasjonsanalyseverktøy brukes også av teknikerne. De måler små vibrasjoner i smart rørposisjonsregulator komponenter. Hvis vibrasjonene føles unormale, kan det indikere at en del er slitt eller ikke fungerer som den skal. Xiangjing anbefaler regelmessige vibrasjonskontroller for å oppdage problemer tidlig. I tillegg bruker noen av de mer avanserte diagnostiske instrumentene trådløse sensorer som sender data i sanntid tilbake til en datamaskin eller telefon. Dette gir teknikere mulighet for fjernaksess og visning av ventilposisjonsgivere for å oppdage et problem mens de er på vei, før et større problem inntreffer. Denne typen data kan også skannes av programvareprogrammer for å utløse varsler når noe går galt. Denne typen smart teknologi tilbys i økende grad på markedet. Infrarødkameraer er også populært utstyr for å analysere varmeendringer i ventilposisjonsgivere. Friksjon eller elektriske problemer kan forårsake for mye varme. Teknikere kan ellers oppdage disse problemene uten å demontere enheten ved hjelp av infrarødkameraer. Til sammen kan man si at når det gjelder diagnostisk utstyr som er i ferd med å bli populært, vil disse hjelpe til å forenkle søket etter og reparasjon av intermittente feil i pneumatisk ventilposisjonsgivere. Xiangjing oppfordrer til bruk av disse verktøyene for å forbedre vedlikehold og minimere nedetid for utstyr. Med de rette verktøyene kan teknikere sikre at ventilposisjonsgivere fungerer med topp effektivitet over svært lang tid.

Innholdsfortegnelse

- Vanlige luftproblemer i stilleverk for reguleringsventiler og hvordan de kan unngås

- Pålitelige ventilstillingsautomater bygget for kontinuerlig ytelse - Hvorfor Xiangjing er det trygge valget

- Kva er den beste tilnærminga til å diagnostisere feil på intermittente ventilposisjoneringsapparat?

- Hvordan utføre kvalitetskontroll i pneumatiske ventilstillere?

- Relevante diagnostiske verktøy som er populære på markedet for feil ved pneumatiske ventilstillinger

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK