For personer som har interesse i olje- og gassboring, er kunnskap om annekulær BOP-teknologi nyttig. En annekulær BOP (en blowout preventer), er et viktig stykke utstyr for å kontrollere olje- og gassstrømmen innenfor en brønn. Den settes over brønnen og fungerer som en blowout preventer.

Favorable trekk er knyttet til bruk av en annular BOP for olje- og gassforing. Et av de hovedfordelene er at den gir en ekstra lag med beskyttelse mot utbrudd og andre problemer. Ved å ha en annular BOP på plass, kan drillearbeidere forhindre farlige hendelser fra å oppstå og beskytte alle personell på foringsstedet.

For å sikre at annulære BOP'er er effektive, er vedlikehold og sikkerhetsforholdsregler veldig avgjørende. Routinemessige kontroller og tester må gjennomføres for å oppdage eventuelle problemer og løse dem umiddelbart. Arbeidere må også få trening slik at de kan operere annulære BOP'er på en sikker måte for å unngå ulykker på linjen og sikre helsen og sikkerheten til alle.

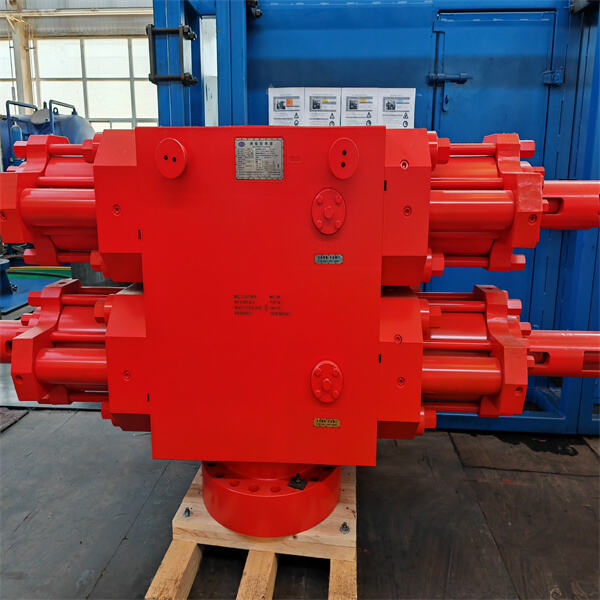

Borere kan visualisere de unike fordelsene med denne teknologien ved å sammenligne annulære BOP'er med andre verktøy. Mens ramme-BOP'er lukker brønner med, vel, ramer, bruker annulære BOP'er en donutsformet del av spesialgummie for å kontrollere strømmen av olje og gass. Dette gjør at annulære BOP'er ofte blir valgt i en stor andel av boreoperasjonene, grunnet de mer agil og enkle operasjonene de tillater.

Effekten av annekulare BOP-er i forhindring av blowouts og lignende er ekstremt betydelig. Annekulare BOP-er fungerer for å gjenopprette kontrollen over boreoperasjonen og redusere verre situasjoner ved å raskt lukke av brønnen i nødsituasjoner. Dette betyr en sikrere arbeidsmiljø for alle involverte i boring.