- Početna Stranica

- O Nama

-

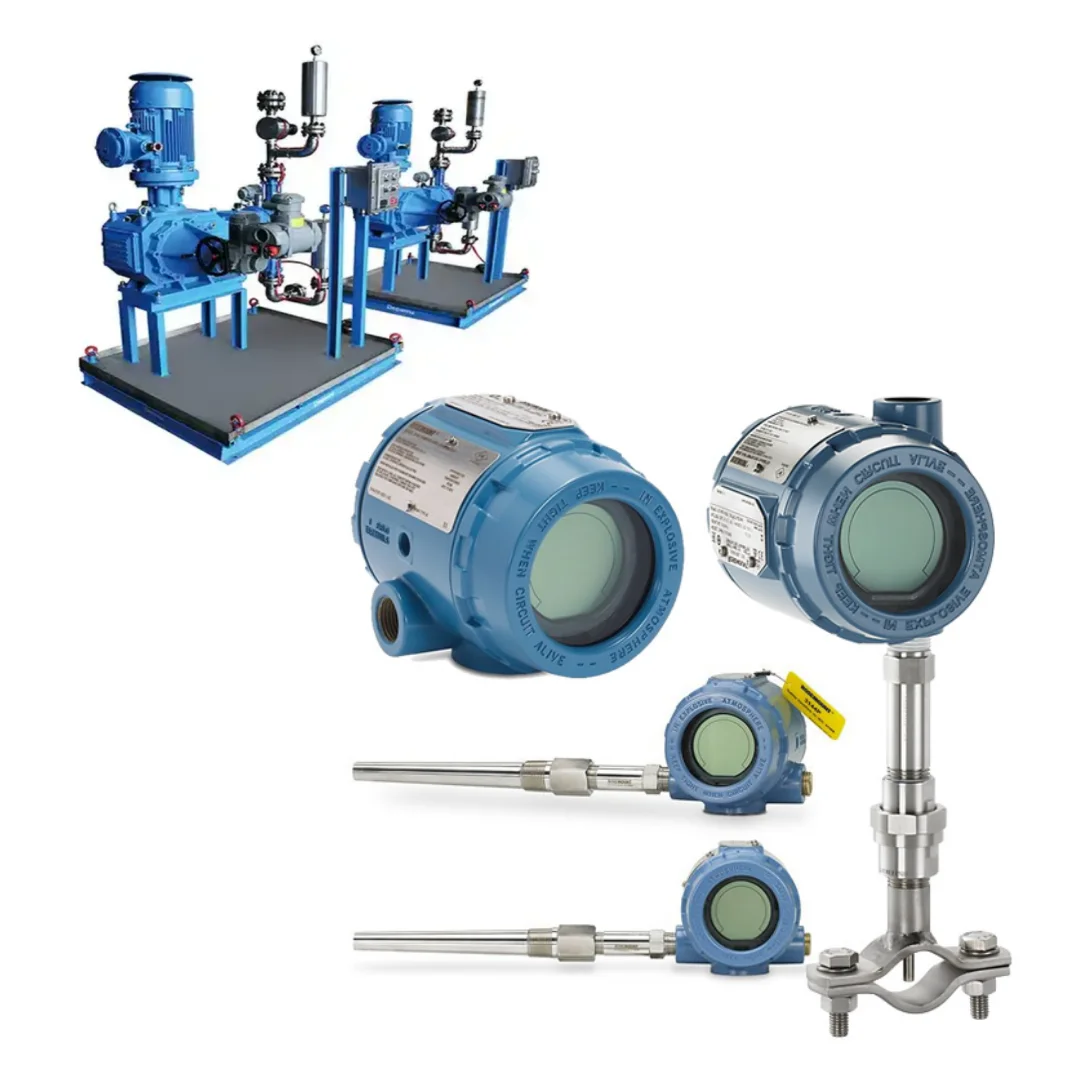

Proizvodi

Ventili I Pribor

Bušačke I Radne Jedinice

Kontaktirajte nasTel / WhatsApp / WeChat:

+86 15000725058

- Vijesti

- Kontakt

- Blog

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK