The Uses Of Natural Gas Compressors In Industry

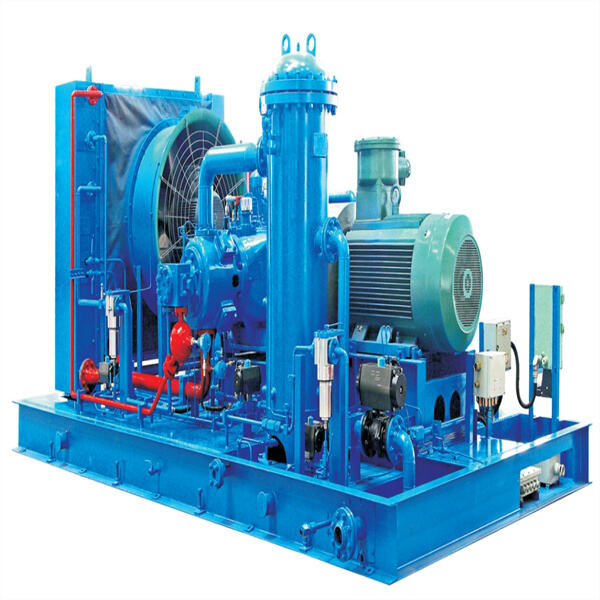

Natural gas compressors are used for transporting natural gases from one point to another in industrial systems. These devices play an important role in increasing the pressure of natural gas so that it can be moved from one place to another which could include distribution by pipeline, or storage and BOTAS Natural Gas Treatment facilities. Utilizing compressors to raise the pressure of natural gas allows it to be used in other industrial processes and helps with overall plant efficiency.

Natural gas compressors come in a variety of options, each option designed to meet the needs individual industrial settings. Heavy-duty industrial processes, such as some that need high-pressure compressed air, lean on resilient but economical compressors like the Atlas Copco HHE rotary screw compressor and Kaeser SM 15T; while plants with robust throughput needs are sustained by units similar to Ingersoll Rand C400 and C600 centrifugal compressors. Moreover, gas industry uses compressors such as Ariel JGQ and JGC natural gas reciprocating models which are highly compact in size with higher capacity to weight ratio with lower maintenance restrictions demanded by the customer oriented for easy service demands making it more unique on application at hearth of the most demanding block production.

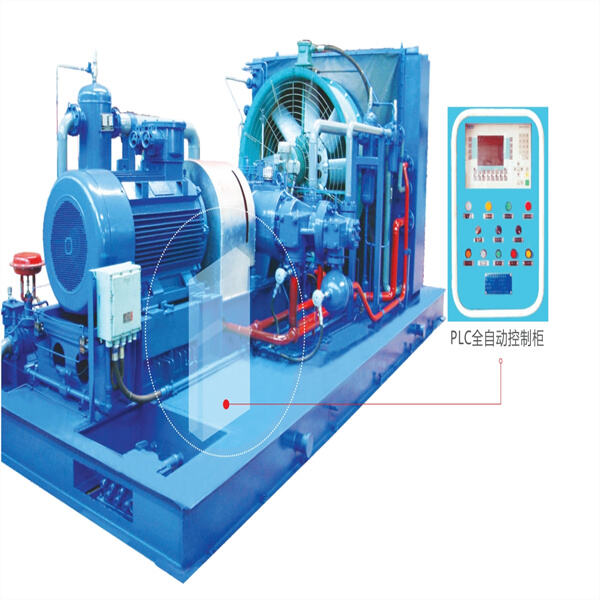

A relatively new technology has entered the natural gas compressor package game. With advanced features including variable speed drives for improved efficiency and control, as well as data analytics for remote monitoring of system performance these modern compressors have been designed to lead the 21st century technology race. All of these engineering advancements have since contributed to a more efficient and stable natural gas compressor performance, thus overall industrial efficiency greatly benefits from this.

What Is The Importance of Maintenance Practices

Natural gas compressors are an important component used to transport natural, and essential maintenance is required to keep them running well. A proper maintenance program that consists of regular component checks, cleaning and replacements done in a timely manner is essential for the compressor performance to be maximized over time. It is critical to maintain a close watch on important operating parameters such as pressure and temperature, in the event these deviate from their respective target values that could have an impact compressor efficiency.

Offshore and onshore production environments can call for different compressor solutions in order to address their specific demands. Modular compressor systems are versatile and energy-efficient, providing cost-effective solutions for several suggestions. Designed for onshore and offshore production the EV-SA 10 modular compressor from Japanese manufacturer Ebara, is said to be efficient in operation with a small footprint; reducing costs of installation. The Ariel JGJ and JGT gas compressors are also highly versatile due to their lightweight construction that is supported by fewer parts.

Compressors are the heartbeat of gas production systems. With the selection of proper compressors and regular maintenance, gas flow rates can be increased whereas repairs cost with lower energy consumption.

Our gasoline and oil equipment is natural gas compressor, which is the pinnacle in quality and ingenuity. Every product is meticulously crafted by R and D and manufacturing experts to meet or exceed customers' expectations and set new standards in the field.

With natural gas compressor, we serve customers from all over the world. We can offer localized services all over the world since our team is well understanding of different regional markets. We have a great understanding of the needs of each customer and solving complex problems across different markets.

Every needs for automation in your natural gas compressor. We have more than 10 years of experience in developing manufacturing selling and distributing our own products. We are as well representing international brands. Our wide ranges of products spans many sectors and ensures tailored solutions to meets the needs of each customers.

Our team of 500+ guarantees continuous support throughout your entire journey. Our natural gas compressor from pre-sales to after-sales. We can provide visits on-site welcome clients to China and ensure an open line of communication fostering lasting relationships and accelerating industry growth.