Cooling the gas to extreme temperatures and turning it into a liquid is extremely important, and thtanh / Getty Images An LNG compressor is an industrial machine that helps make the natural gas really cold. It is simply a way in which methane exists and it has turned into a liquid state, thereby we name this form of natural gas as Liquefied Natural Gas (LNG). This article will give the detailed information on what is an LNG compressor, how does it work and why is this so important along with a look at some of its technology.

This is the main purpose that LNG compressors serve, moving gas from point A to point B. Liquid natural gas as the name implies is when natural gas has been chilled an extremely low -260°F, turning it into vapor. The incredible process is called liquefaction, and the machines that perform it are LNG compressors.

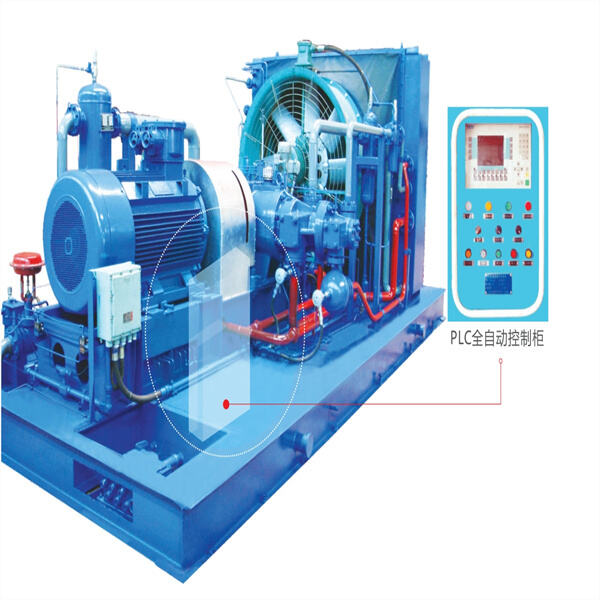

So using large amounts of electricity they work in powerful machines and deploy this energy converting natural gas to a liquid. The process starts with a compressor compressing natural gas and raising its pressure. The gas is then slowly cooled until it condenses into a liquid state. The machine liquefies natural gas and the compressed, liquid forms then get pumped to a huge tanker which ships it elsewhere. That allows us to transport natural gas more conveniently and safely.

One of the steps to increase efficiency in a LNG compressor is by employing materials made specifically for this type of use on the valves. These proprietary materials are engineered to survive the extremely cold temperatures and high pressures that occur in this process. Lastly, some compressor configurations are capable of capturing energy normally lost in compression - achieving even greater efficiency.

One way to increase efficiency is by minimizing the number of stages that a substance has to undergo in order for it be compressed. More stages mean more energy is required to run the compressor. The end result is a more efficient and overall less energy hungry LNG compressor due to how fewer stages can be operating in the process.

An example of a high-level compression system is the magnetic bearings. These bearings work by using a magnetic field to levitate the compressor shaft, eliminating any friction between moving parts. That reduced friction makes the whole compressor system work more efficiently, requiring less energy to run. This, in turn reduces operational costs and also decreases Emissions.

One more example could be advanced compression systems operating on a variable speed drive. Such drives enables the compressor to have speed variation in accordance with the compressed gas. But they increase the compressor's capacity to unload and operate more efficiently at lower speeds, which means less energy is consumed (and fewer emissions produced). By doing this, it provides more opportunities to use energy wise.

Our lng compressor and oil equipment comes from the top Chinese manufacturers and is the pinnacle in quality and ingenuity. Each piece of equipment is meticulously created by R and D and manufacturing experts in order to meet customer expectations, and to set new standards for the industry.

Every need for automation in your industry are met by us. With more than a decade's expertise we lng compressor, distribute, and sell our own products while also representing top international brands. Our wide ranges of products spans many industries and provides a customized solutions to each customer.

Our lng compressor will provide seamless assistance throughout your journey. From pre-sales to after-sales support our specialists provide professional assistance at each step. We welcome clients from China meet on site and provide open channels of communication to create lasting partnerships.

With lng compressor, we provide clients worldwide. We can provide localized services around the world because our team has an extensive understanding of different regional markets. We are experts at addressing the needs of each customer and solving difficult problems across different markets.