The oil and gas industry is not so few, the most important of which are bop valve. This is an important safety feature to have in place while drilling, it helps provide a safe working environment. Extracting oil and gas is an inherently risky process involving multiple, complexly executed steps; the bop valve provides for at least one of thoseclang! Learn more about the bop valve and why it is so important!!

BOP valve = blowout preventer valuethe tool allows drillers to circulate oil or gas through the well. Your BOP valve will be used to close the oil or gas in case of emergency. A large and space instrument installed with drilling equipment forever. So it is already usable in an emergency. Without the bop valve, the drilling operation was likely extremely unsafe.

This includes a bop valve etc due to the drilling. Maintenance Taking care of your equipment to keep your them going strong when you need it most! Frequently troubleshooting or servicing help to avoid, and identify potential problems before they change into considerable. Many operators seek early indications of problems, such as routine monitoring of the bop valve to identify issues sooner rather than later. Routine maintenance should be carried out with this equipment to guarantee it stays safe and no occurrence takes place in the rift.

Drilling for oil and natural gas is a risky job. They can result in explosions and fires since the risks listed above are present. Blowout is something, which bop valve helps to be avoided A blowout is the uncontrolled escape of gas or oil from a well, and it can be at once exceedingly dangerous and destructive for an area. Fortunately, the bop valve prevents this from happening it allows everyone on the drilling site to be safe.

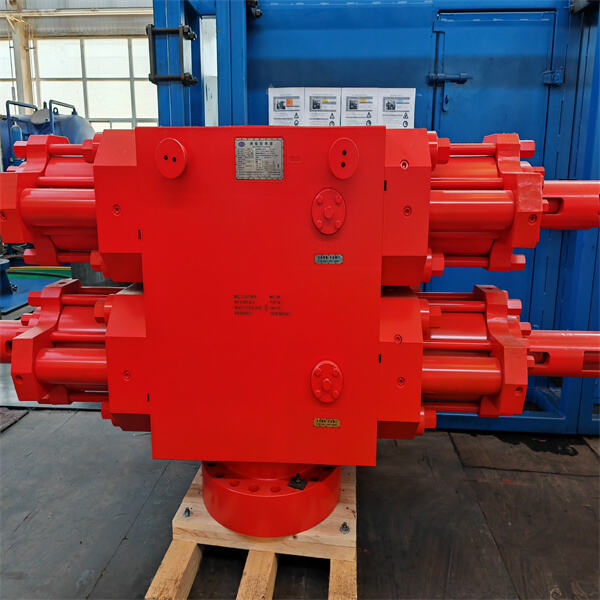

The types of bop valves used in the oil and gas industry Each variant is made for same boring situations but different places follow. OutlookOnshore the is drilling one provision of some bop valves and another inside the sea ocean. There are two types of bop valves, generally named an annular blowout preventers and a ram blowout preventers. Annular Blowout Preventer seals around drill-pipe, and Ram-type BOP is used to fill in sealer subs and seal-off wellbore for emergency interception. It is really important for you to know what these types of valves are and how they differ, in order not to endanger your security when it comes to drilling operations.

Naturally, drillers and operators need to understand proper use of the bop valve. That does not demand we teach all of them how to drive that or run it and also inspect this, In the event one thing goes wrong they possess guidelines on ways to utilize the bop shutoff at the same time. There is a right way to use this and you must be certified before using it. This training makes certain that we are all safe while drilling and can respond to any issues accordingly.

Every need for automation in your industry will be fulfilled by our teams. With more than a bop valve we develops production, distribute, and sell our own products and represent the top international brands. Our extensive portfolio spans multiple industries providing a customized solutions to each customer.

Our bop valve guarantees an unbeatable level of support during your entire journey. Our professionals provide expert assistance starting from pre-sales right through after-sales. We welcome customers from China meet on site and provide open channels of communication to create long-lasting relationships.

Our gasoline and bop valve is procured from top Chinese manufacturers, and is the very best in quality and ingenuity. Each item is meticulously designed by R and D and manufacturing experts to surpass customer expectations, and to set new standards in the industry.

With bop valve, we provide clients worldwide. We can provide localized services around the world because our team has an extensive understanding of different regional markets. We are experts at addressing the needs of each customer and solving difficult problems across different markets.